Products / Welding manipulators & Rotators / Rotators

MAR – Rotator

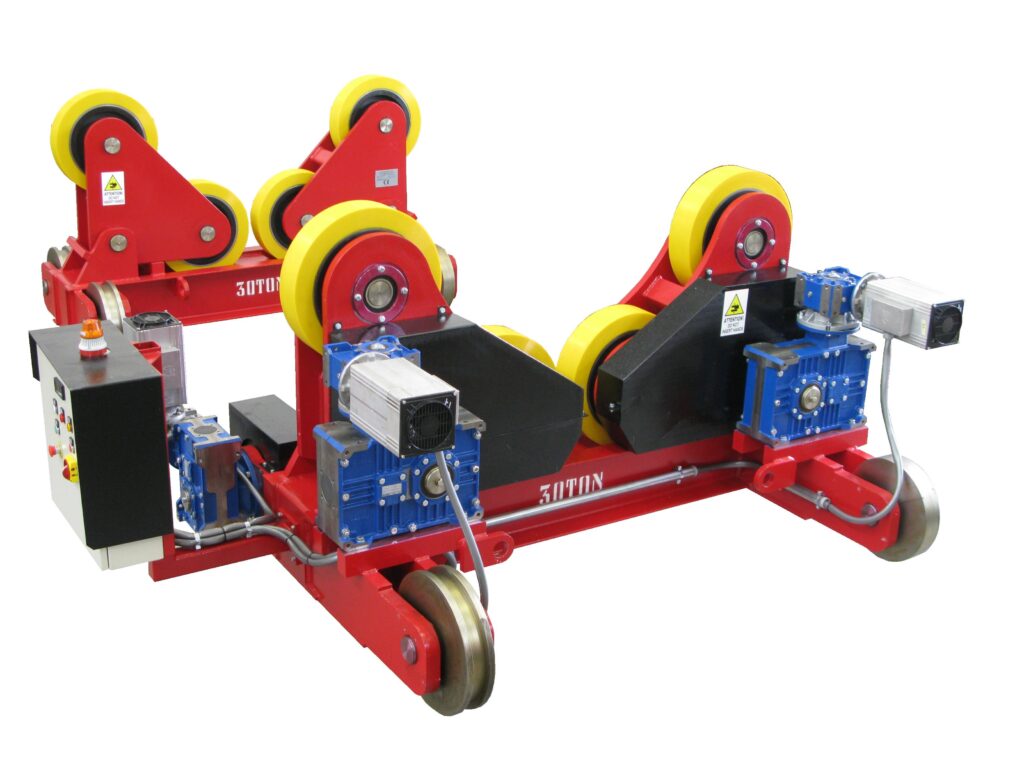

MAR – Manual-aligning rotator

The MAR series conventional rotators positioners are the most economical and flexible units, ideal for a variety of different applications. These units allow rotation and positioning of cylindrical items and are capable of handling a wide range of different diameters due to the fact that the distance between the rolls is adjustable. Normally made up of a motorized unit followed by a free-running one, they can be equipped with both a fixed base and a trolley base for variable speed freewheel movement on rails and can be synchronized with welding devices such as Column & Boom manipulators.

On request, these units can also be made specifically for use in painting and sandblasting booths and can be equipped with a hydraulic adaptation system.

| MAR | |

|---|---|

| FIT-UP VERSION | Available |

| TYPE OF BASE | Fixed or motorized |

| TYPE OF ALIGNMENT | Manual |

| LOAD CAPACITY | From 10 to 120 Tons |

In Corimpex we produce high-quality accessories and we provide an efficient after-sale service, which confirm the reliability of a Made In Italy company, world leader in the industry segment.