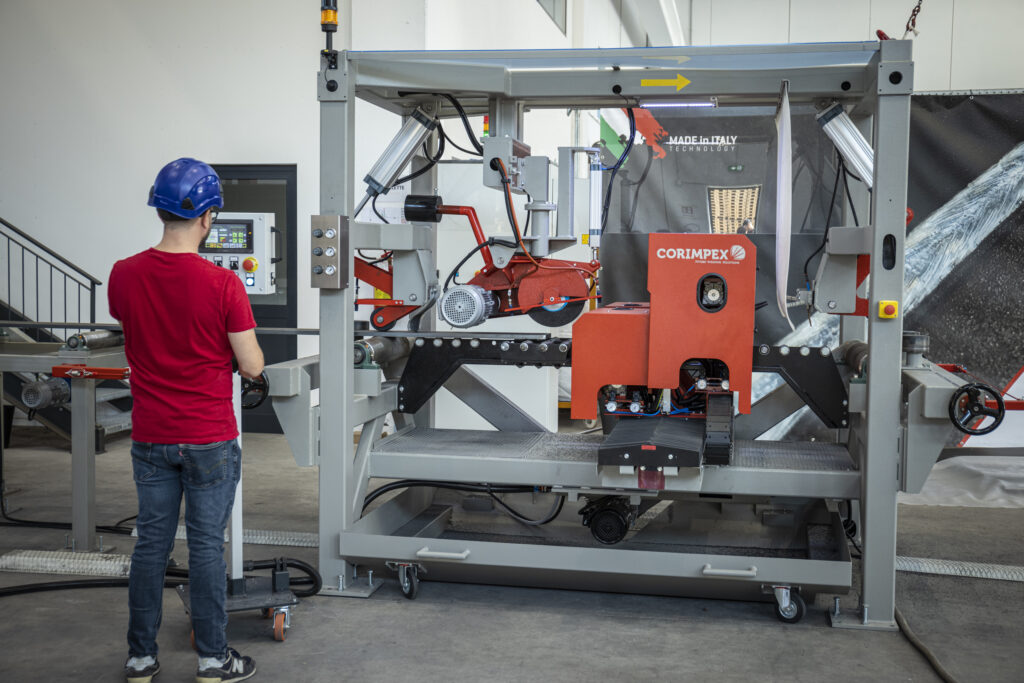

Products / Beam welding line / Vertical solution

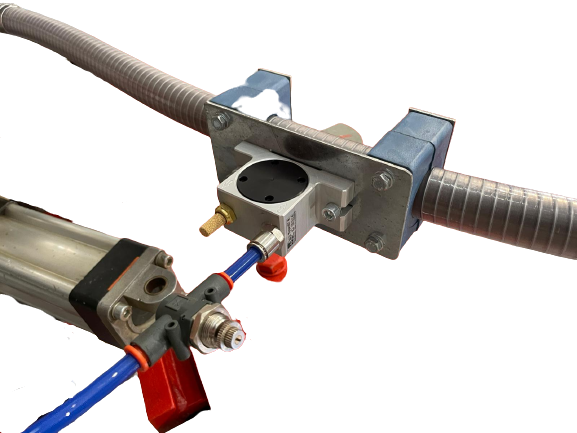

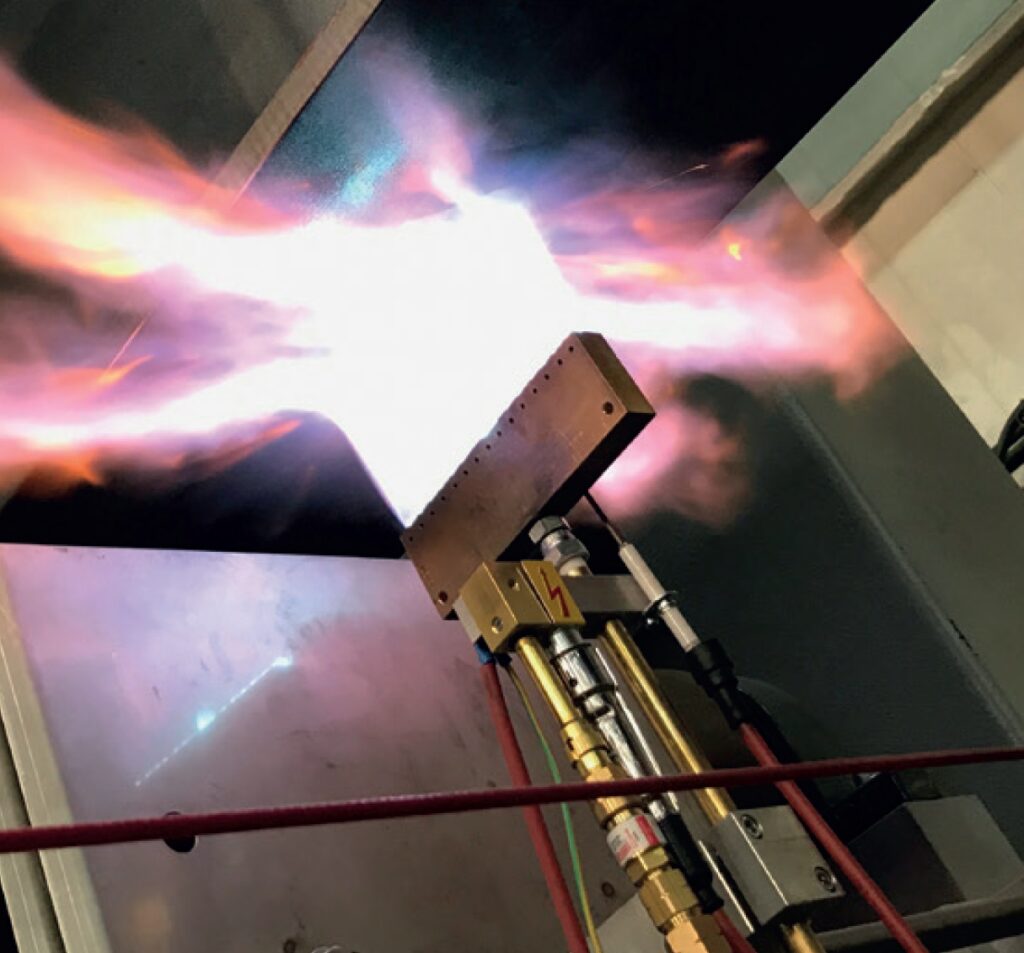

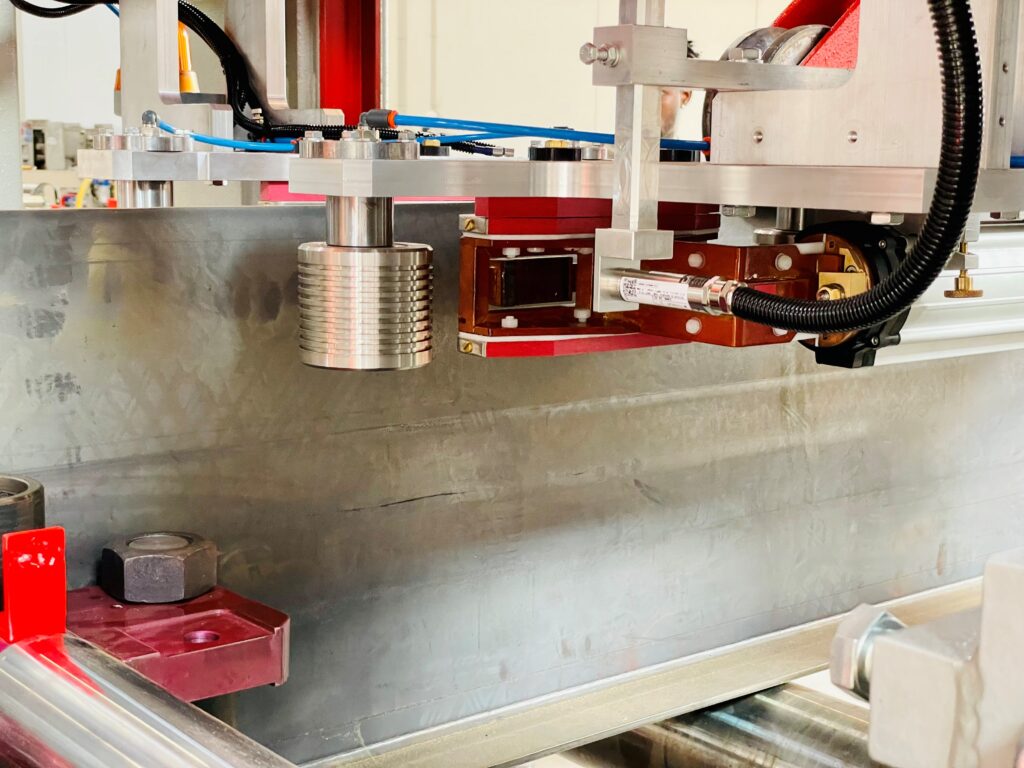

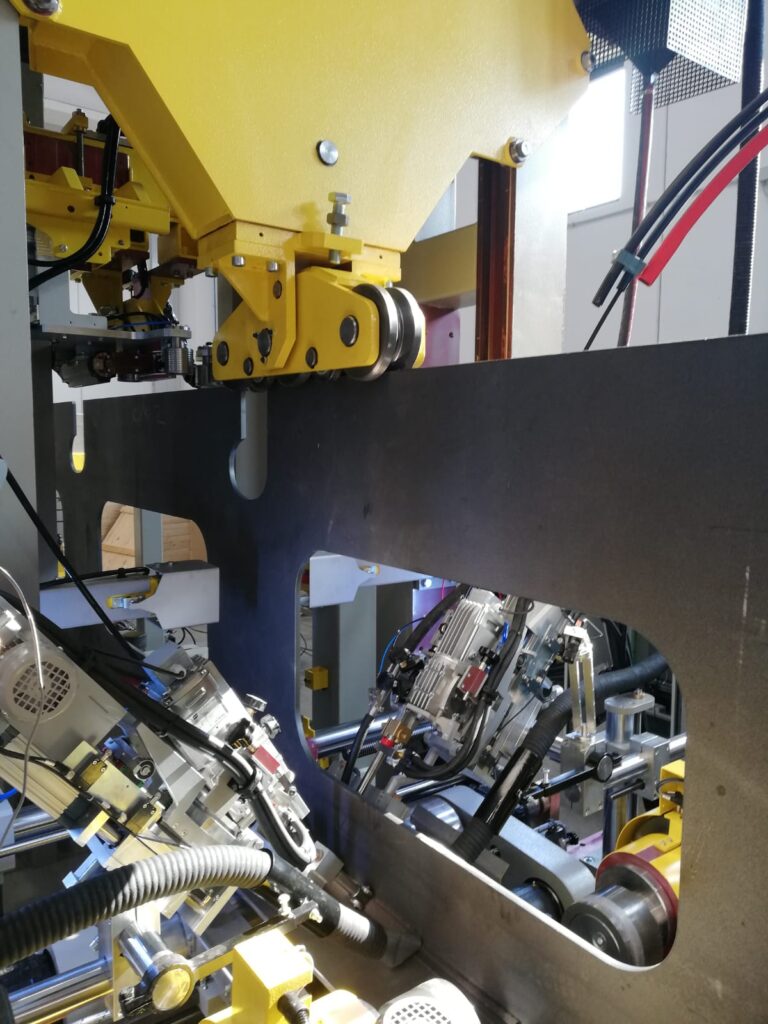

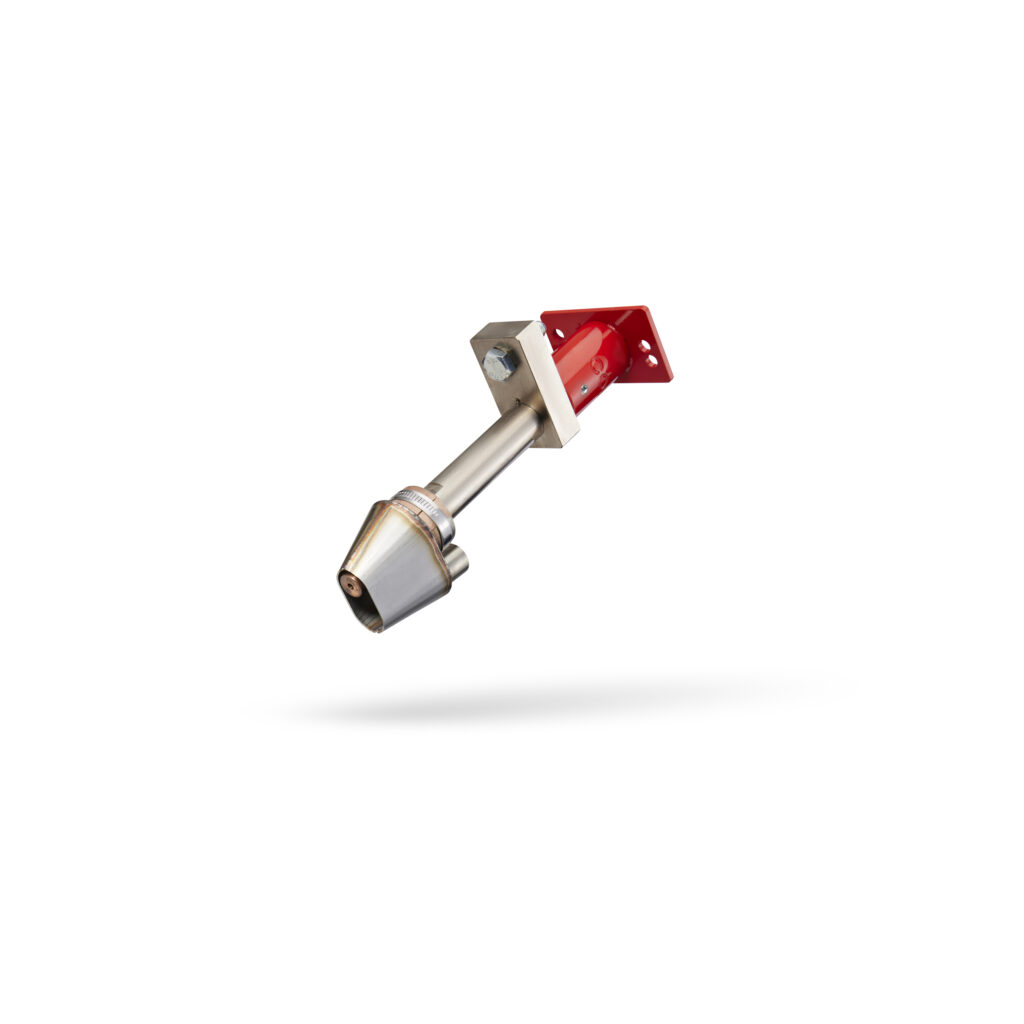

BWM-TC – Beam Welding Machine

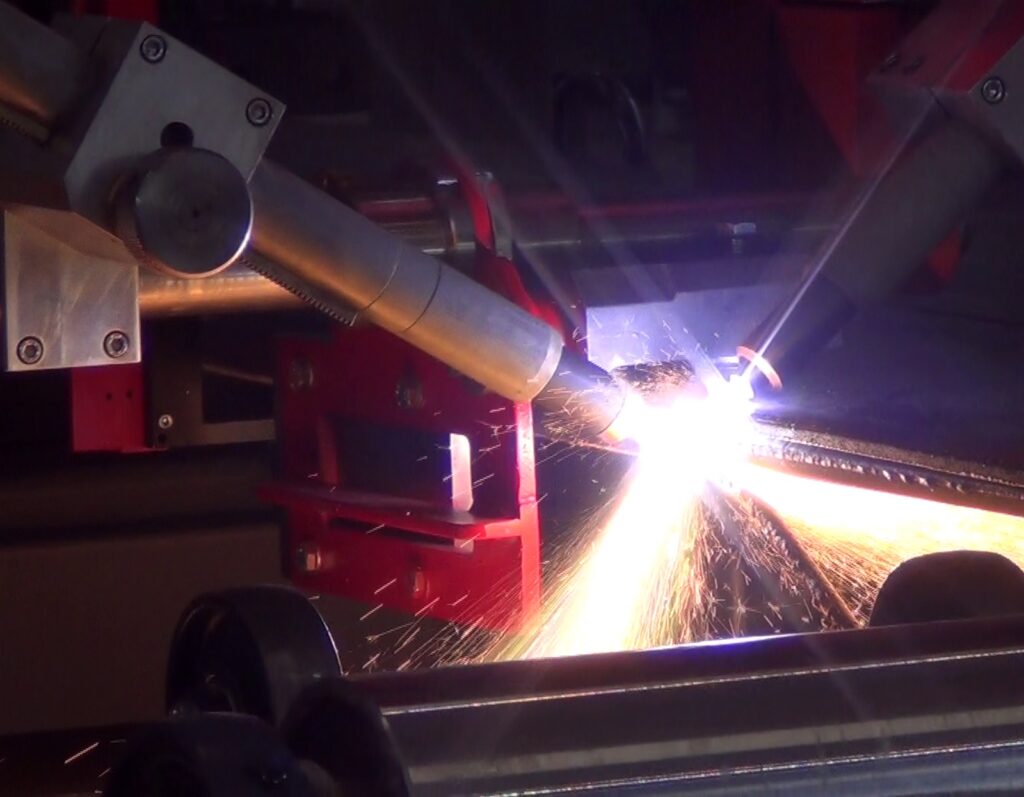

The BWM-TC series represents the most advanced and flexible automatic solution in the world for the production of welded T and I beams, as well as other non-standard beams.