Find out more

Products

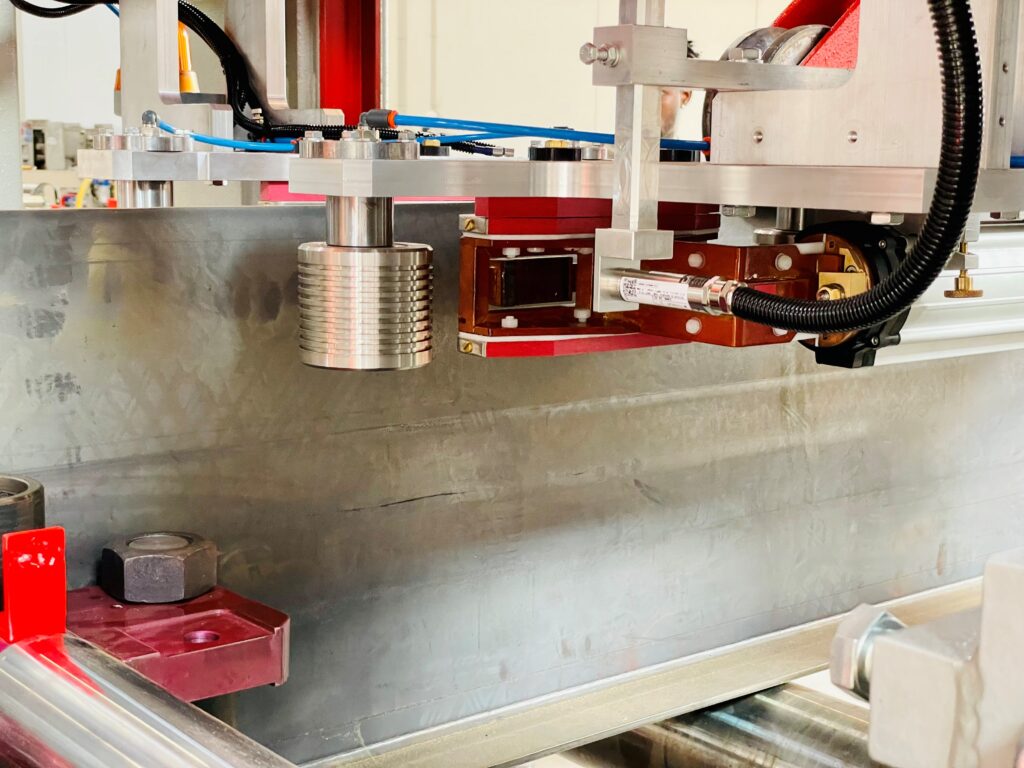

Corimpex machines are specialized in the automation of submerged arc welding processes and related steel plates preparation processes.

Corimpex machines are specialized in the automation of submerged arc welding processes and related steel plates preparation processes.

It represents the worldwide most advanced and flexible automatic solution for the production of welded beams. This line allows customers to reach the highest level of productivity thanks to the less needs of the overhead crane, no requirements of pre-tack weld, integrated flange straightening device and many other options.

These lines are designed for the segment of the lighting steel poles, telecommunication or transmission towers. The PWL represents the most productive solution thanks to the unique reacheable dimensions of work on the market.

A specific line of machines to prepare just-in-time your steel plates before or after the welding process, improving the overall productivity and quality of your workshop.

The latest and innovative lines to cover all your straightening needs to meet your steel construction tolerances. Flange distortion, undesired camber and sweeping are no more an issue.

The TCW line has been engineered on welding fixture to optimize the productivity of the trailer chassis fabrication. The main distinction of this line is the ability on following shaped beams during the welding process.

A wide range and sizes of sub-arc welding Column & Boom and rotators for many different industry segments such as of Oil & gas, wind towers, pressure vessels, boilers and petrochemicals.

Our patented innovative solution in the field of welded H, T and I beams. A single Beam welding system that allows to manufacture the beam without the need of the overhead crane during the whole production cycle.

The reliability of the company and of our production lines is confirmed every day by the after-sales support followed directly by our qualified team.

The Services are:

In Corimpex we produce high-quality accessories and we provide an efficient after-sale service, which confirm the reliability of a Made In Italy company, world leader in the industry segment.